As part of a series of articles based on a recent online roundtable event entitled ‘From research to manufacturing: Overcoming data challenges in the drug development cycle’, hosted by Scientific Computing World, we asked our panellists about data ontologies and how they can help improve efficiency in process development.

“Time-to-market is money,” says Lukas Kürten, Digital Innovation Manager at CPI. “If you’ve got a process that works, you’ve got to throw it into manufacturing, because you’ve got to milk your patent as long as it’s alive.” Issues with data – at whatever stage of the development process – can cause costly delays in bringing a drug to market.

Kevin Back, Product Manager at Cambridge Crystallographic Centre (CCDC), gives an example. “When you’re coming to production, if you get an analytical result that’s out of the ordinary, you’ll want to look back to see if it’s happened before or matches a previous pattern you’ve seen. Poor decisions around storage – or indeed data being stored in older systems – can prevent this historical data search.”

Moritz von Stosch, Chief Innovation Officer at DataHow, says: “The data that we generate early on is the knowledge backbone. It’s an asset we may constantly need to go back to in order to understand what is going on. If we consistently map the data from very early on in process development, through drug testing and into manufacturing, then we have that knowledge backbone. A PDF report, by definition, is subject to interpretation, whereas having consistent access to the raw data allows us to ask new questions of it later in the process.”

Jackie Lighten, Program Manager at Cell and Gene Therapy Catapult, adds: “There can be naivety when setting up a manufacturing lab or developing manufacturing equipment, driven by not designing in quality and data integrity standards from the start. Something that is fit for the research lab may not be fit for a GMP (Good Manufacturing Practices) grade lab that produces therapies for human use.

“We encourage our partners to have a risk-based approach to introducing innovation into a GMP environment, which relies on having a good QA (Quality Assurance) and validation team, who can evaluate new research equipment and how they will impact on existing, proven processes.”

“You have to take a pragmatic approach,” says Nick Lynch, Founder at Curlew Research. “There are so many stakeholders involved in data: both the creators and the consumers. Change management is just as important as the tooling. You’ve got a lot of work to do with the client and external parties to try and get that change management working, because there’s no single bit of magic here. It’s going to be a journey for everyone that’s likely to take years, not days, depending on the amount of data points.”

A method to overcome this is to agree on a common language across various data sets. “In a recent project,” continues Lynch, “we developed a set of vocabularies early on that were designed to help the adoption transfer. It made the step from late-stage development to early-stage manufacturing easier, as we used a common language. It wasn’t fancy – a vocab style rather than an ontology – but it was effective. Those involved in later stage analytics found the data was in a much better shape and it made analytics and digitalisation much easier.”

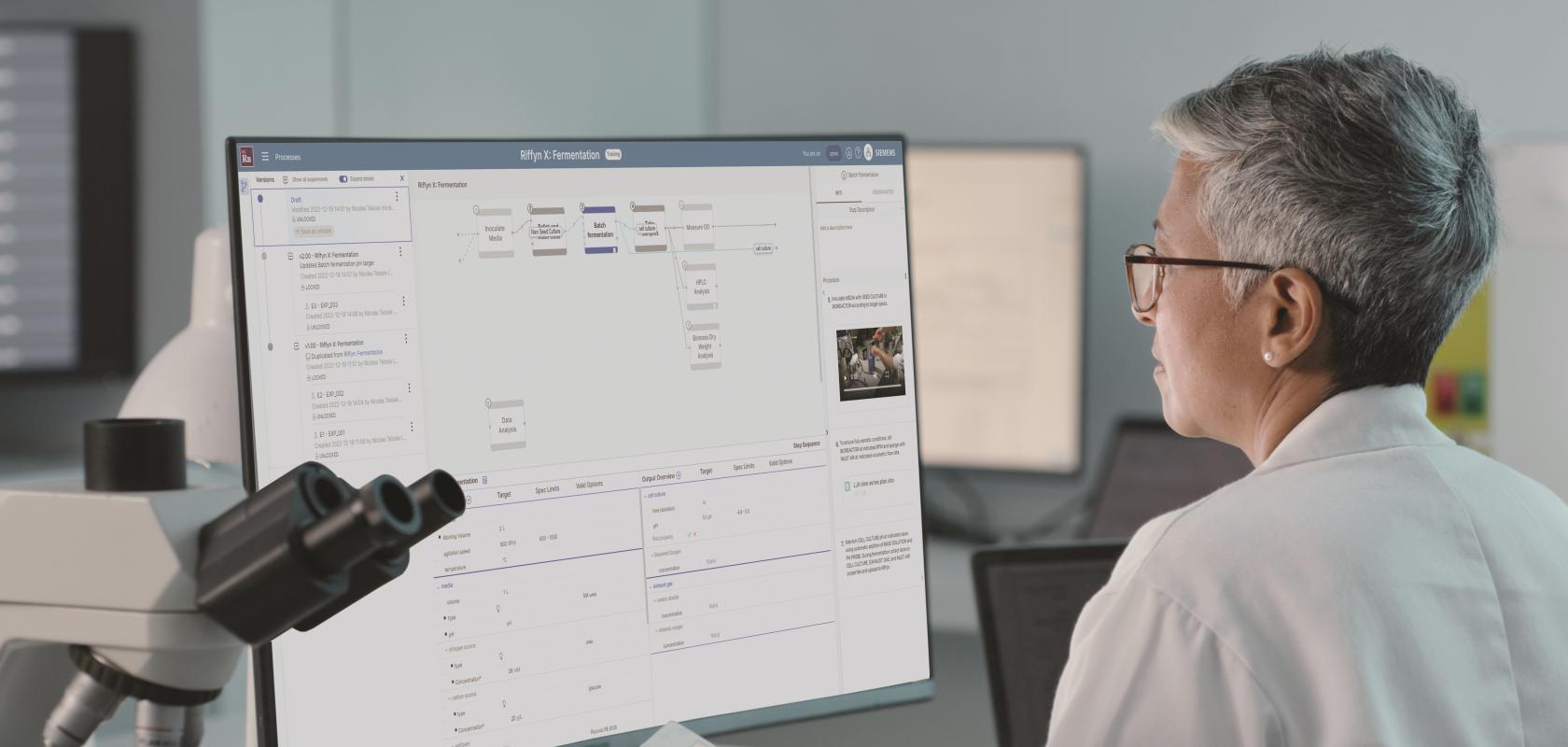

Jim Thompson, Medical Devices and Pharmaceuticals Industry Lead, Siemens Digital Industries Software, concludes: “There’s an inherent trade-off when it comes to speed. You may get to an answer that may be suboptimal, particularly when thinking about scaling across clinical trials and into commercial production. You may find yourself in a spot that doesn’t lend itself to large-scale efficiency, or it may expose a fragility of process. What may be ‘acceptable’ early on in the development process might turn out to be ‘less than acceptable’ for later stages, so getting people to think about things earlier is a real challenge.”

The full report is available to download as a White Paper here, which also covers: Data collection and formats; Data silos and how to avoid them; Cultural change and the digitisation journey; The shift to in silico for experiments; and Process optimisation and technology transfer.

The roundtable and series of articles is sponsored by Siemens Digital Industries.